|

Brand Name &Classification |

Weld Metal Analysis Typical values |

Typical Mechanical properties |

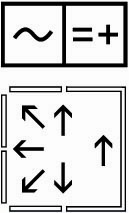

Welding positions |

|||

|

Yield Strength |

Tensile Strength |

Elongation |

Impact Strength |

|||

OVERCORDAWS/ASME SFA-5.1: E6013 DIN 1913: E 43 22 R(C)3 EN499: E 38 0 RC 11 |

Carbon: 0.08 Silicon: 0.30 Manganese: 0.55

|

>390 N/MM2

|

470 – 590 N/mm2

|

> 22 % |

80 J at +200 c 50 J at 00 c

|

|

SUPERCITOAWS/ASME SFA-5.1:E 7018 DIN 1913: E 51 55 B 10 EN 499: E 42 6 B 42 H 10 |

Carbon: 0.08 Silicon: 0.50 Manganese: 1.10

|

>420 N/MM2 |

500 – 640 N/mm2 |

> 26 % |

200 J at +200 c 150 J at 00 c 80 J at -600 c |

|

|

ZELCORD 60 AWS/ASME SFA-5.1:E 6010 DIN 1913: E 43 43 C 4 EN 499: E 35 2 C 25 |

Carbon: 0.10 Silicon: 0.50 Manganese: 0.60

|

>410 N/MM2 |

470 – 560 N/mm2

|

> 23 % |

90 J at +200 c 50 J at -200 c

|

|

ZELCORD 70AWS/ASME SFA-5.5: E7010 G EN499: E 38 2 C 25

|

Carbon: 0.10 Silicon: 0.20 Manganese: 0.40 Molybdenum: 0.40 |

>420 N/MM2 |

500 – 640 N/mm2

|

> 26 % |

90 J at +200 c 50 J at -200 c

|

|

TENACITOAWS/ASME SFA-5.1 E 7018-I DIN 8529: E SY 42 76 Mn B EN 499: E 42 6 B 42 H5 |

Carbon: 0.06 Silicon: 0.30 Manganese: 1.45

|

>420 N/MM2

|

500 –640 N/mm2

|

> 22 % |

180 J at +200 c 60 J at-600 c

|

|

MOLYCORDAWS/ASME SFA-5.5: E 7018-A1 DIN 8575: E Mo B 20 EN 1599: E Mo B 42 H10 |

Carbon: 0.06 Silicon: 0.50 Manganese: 0.80 Molybdenum:0.50 |

>470 N/MM2 |

520 – 650 N/mm2 |

> 22 % |

160 J at +200 c

|

|

VERTICITOAWS/ASME SFA-5.4: E 7048 DIN 1913: E 51 43 B 9 EN 499: E 42 2 B 15 H 10 |

Carbon: 0.08 Silicon: 0.60 Manganese: 1.10 |

>420 N/MM2 |

500 – 640 N/mm2 |

> 23 % |

100 J at +200 c 55 J at -200 c

|

|

SPEZIALAWS/ASME SFA-5.1: E 7016 DIN 1913: E 51 43 B (R) 10 EN 499: E 38 2 B 12 H 10 |

Carbon: 0.06 Silicon: 0.70 Manganese: 0.90

|

>380 N/MM2 |

470 – 600 N/mm2 |

> 26 %

|

150 J at +200 c 100 J at -200 c

|

|

SUPRANOX E 308LAWS/ASME SFA-5.4:E 308L-16 DIN 8556: E 19 9 LR23 |

Carbon: 0.03 Silicon: 0.40 Manganese: 1.00 Chromium: 19.0 Nickel: 10.0 |

>400 N/MM2 |

550 –620 N/mm2 |

> 35 % |

75 J at +200 c

|

|

SUPRANOX E 316LAWS/ASME SFA-5.4:E 316L-16 DIN 8556: E 19 12 3 LR23 |

Carbon: 0.03 Silicon: 0.80 Manganese: 0.80 Chromium: 18.5 Nickel: 12.0 Molybdenum: 2.70 |

>420 N/MM2 |

520 – 580 N/mm2 |

> 35 % |

65 J at +200 c

|

|

SUPRANOX E 309LAWS/ASME SFA-5.4: E 309L-16 DIN 8556: E 23 12 LR 23 |

Carbon: 0.03 Silicon: 0.80 Manganese: 0.70 Chromium: 24.0 Nickel: 13.0 |

>400 N/MM2 |

520 – 580 N/mm2 |

> 30 % |

60 J at +200 c

|

|

SUPRANOX E 347AWS/ASME SFA-5.4: E 347-16 DIN 8556: E 19 9 Nb R 23 |

Carbon: 0.025 Silicon: 0.90 Manganese: 0.80 Chromium: 19.0 Nickel: 10.0 Niobium: 0.40 |

>420 N/MM2 |

540 – 620 N/mm2 |

> 33 % |

60 J at +200 c

|

|

SUPRANOX E 310AWS/ASME SFA-5.4: E 310-16 DIN 8556: E 25 20 R 23 EN 1600: E 25 20 R 23 |

Carbon: 0.10 Silicon: 0.50 Manganese: 4.50 Chromium: 25.0 Nickel: 20.0 |

>400 N/MM2 |

550 –620 N/mm2 |

> 35 % |

100 J at +200 c

|

|

SUPERFONTE NiAWS/ASME SFA-5.15 E Ni CI DIN 8573: E Ni BG-22 |

Carbon: 0.50 Iron: 2.00 Nickel: Balance |

>200 N/MM2

|

380 – 420 N/mm2 |

> 5 % |

Hardness HB 140

|

|

|

SUPERFONTE Ni Fe AWS/ASME SFA-5.15: E NiFe-CI DIN 8573: E NiFe-1 BG-22 |

Carbon: 0.50 Iron: Balance Nickel: 55.0 |

>300 N/MM2 |

420 – 460 N/mm2 |

>10 % |

Hardness HB 170

|

|

|

SUPERFONTE Ni Cu AWS/ASME SFA-5.15: E NiCu-B DIN 8573: E NiCu BG-22 |

Carbon: 0.50 Iron: 4.00 Nickel: Balance Copper: 30.0 |

>200 N/MM2 |

380 – 420 N/mm2 |

>1 5 % |

Hardness HB 150

|

|

|

CITODUR 600 B

|

Carbon: 0.50 Silicon: 0.40 Manganese: 0.30 Chromium: 7.00 Molybdenum: 0.50 Vanadium: 0.50 |

58 – 63 HRC

|

|

|||

ALCORD 99.5AWS/ASME SFA-5.3: E 1100 DIN 1732: EL-Al 99,5

|

Aluminium: 99.5 Min Others: 0.5 Max |

>30 N/MM2 |

80 N/mm2 |

>30 % |

|

|

ALCORD 5 Si

AWS/ASME SFA-5.3: E 4043 DIN 1732: EL-AlSi 5

|

Aluminium: Base Silicon: 5.00 Iron: 0.30 |

>90 N/MM2 |

160 N/mm2 |

>15 % |

|

|

Alcord 12 SiDIN 1732: EL-AlSi 12

|

Aluminium: Base Silicon: 12.0 Iron: 0.40

|

>80 N/MM2

|

180 N/mm2 |

> 5 %

|

|

|

UNIQUE E 6013AWS/ASME SFA-5.1: E6013DIN 1913: E 43 22 R(C)3EN499: E 38 0 RC 11 |

Carbon: 0.08 Silicon: 0.30 Manganese: 0.55 |

>390 N/MM2 |

470 – 590 N/mm2 |

> 22 %

|

80 J at +200 c 50 J at 00 c

|

|

ZULFI E 6013AWS/ASME SFA-5.1: E6013 DIN 1913: E 43 22 R(C)3 EN499: E 38 0 RC 11 Approvals: LRS, DNV, BV, GL & ABS Grade:2 |

Carbon: 0.08 Silicon: 0.30 Manganese: 0.55

|

>390 N/MM2 |

470 – 590 N/mm2 |

> 22 % |

80 J at +200 c 50 J at 00 c

|

|

ZULFI E 7018AWS/ASME SFA-5.1:E 7018 DIN 1913: E 51 55 B 10 EN 499: E 42 6 B 42 H 10 Approvals: LRS, DNV, BV, GL & ABS Grade:5Y40H5 |

Carbon: 0.08 Silicon: 0.50 Manganese: 1.10

|

>420 N/MM2 |

500 – 640 N/mm2 |

> 26 % |

200 J at +200 c 150 J at 00 c 80 J at -600 c

|

|

|

ZULFI E 6010 AWS/ASME SFA-5.1:E 6010 DIN 1913: E 43 43 C 4 EN 499: E 35 2 C 25 Approvals: LRS, DNV, BV, GL & ABS Grade:2 |

Carbon: 0.10 Silicon: 0.50 Manganese: 0.60 |

>410 N/MM2 |

470 – 560 N/mm2 |

> 23 % |

90 J at +200 c 50 J at -200 c

|

|

ZULFI E 7010AWS/ASME SFA-5.5: E7010 G EN499: E 38 2 C 25 |

Carbon: 0.10 Silicon: 0.20 Manganese: 0.40 Molybdenum: 0.40 |

>420 N/MM2 |

500 – 640 N/mm2 |

> 26 % |

90 J at +200 c 50 J at -200 c

|

|

ZULFI E 7018-1AWS/ASME SFA-5.1 E 7018-I DIN 8529: E SY 42 76 Mn B EN 499: E 42 6 B 42 H5 Approvals: LRS, DNV, BV, GL & ABS Grade:5Y40H5 |

Carbon: 0.06 Silicon: 0.30 Manganese: 1.45

|

>420 N/MM2 |

500 –640 N/mm2 |

> 22 % |

180 J at +200 c 60 J at-600 c |

|

ZULFI E 7018-A1AWS/ASME SFA-5.5: E 7018-A1 DIN 8575: E Mo B 20 EN 1599: E Mo B 42 H10 |

Carbon: 0.06 Silicon: 0.50 Manganese: 0.80 Molybdenum:0.50

|

>470 N/MM2 |

520 – 650 N/mm2 |

> 22 % |

160 J at +200 c

|

|

ZULFI E 7048AWS/ASME SFA-5.4: E 7048 DIN 1913: E 51 43 B 9 EN 499: E 42 2 B 15 H 10 |

Carbon: 0.08 Silicon: 0.60 Manganese: 1.10 |

>420 N/MM2 |

500 – 640 N/mm2 |

> 23 % |

100 J at +200 c 55 J at -200 c

|

|

ZULFI E 7016AWS/ASME SFA-5.1: E 7016 DIN 1913: E 51 43 B (R) 10 EN 499: E 38 2 B 12 H 10 |

Carbon: 0.06 Silicon: 0.70 Manganese: 0.90 |

>380 N/MM2 |

470 – 600 N/mm2 |

> 26 % |

150 J at +200 c 100 J at -200 c

|

|

ZULFI E 7024AWS/ASME SFA-5.4: E 7024 DIN 1913: E 51 43 B 9 EN 499: E 42 2 B 15 H 10 |

Carbon: 0.08 Silicon: 0.40 Manganese: 0.90

|

>420 N/MM2 |

500 – 640 N/mm2 |

> 24 % |

150 J at +200 c 120 J at -200 c

|

|

ZULFI E 8018-GAWS/ASME SFA-5.5: E 8018-G DIN 8529: E Y 50 76 Mn 1 Ni B H5 EN 499: E 50 6 1Ni B 42 H5 |

Carbon: 0.08 Silicon: 0.40 Manganese: 0.90 Nickel: 0.90 |

>510 N/MM2 |

590 –690 N/mm2 |

> 26 % |

150 J at +200 c 60 J at-600 c |

|

ZULFI E 8018-B2AWS/ASME SFA-5. 5: E 8018-B2 DIN 8575: E CrMo 1 B 20 EN 1599: E CrMo 1 B 42 H 10 |

Carbon: 0.08 Silicon: 0.30 Manganese: 0.90 Molybdenum:0.60 Chromium: 1.00 |

>490 N/MM2 |

590 – 660 N/mm2 |

> 26 % |

150 J at +200 c 60J at -300 c

|

|

ZULFI E 8018-C1AWS/ASME SFA-5.5: E 8018-C1 DIN 8529: E SY 42 87 2 Ni B H5 EN 499: E 46 2Ni B 42 H5 Approvals: LRS, DNV, BV, GL & ABS Grade:5Y40H5 |

Carbon: 0.06 Silicon: 0.40 Manganese: 1.10 Nickel: 2.30 |

As Welded >490 N/MM2 stress relieved 15 Hrs at 5800 c >420 N/MM2 |

As welded >600 N/mm2 stress relieved 15 Hrs at 5800 c >550 N/MM2 |

As welded >23 % stress relieved 15 Hrs at 5800 c >20 % |

As welded 150 J at +200 c 60 J at -500 c stress relieved 15 Hrs at 5800 c 150 J at +200 c 80 J at -500 c |

|

ZULFI E 8018-C2AWS/ASME SFA-5.5: E 8018-C2 DIN 8529: E SY 42 87 3 Ni B H5 EN 499: E 46 3Ni B 42 H5 |

Carbon: 0.06 Silicon: 0.40 Manganese: 1.10 Nickel: 3.25 |

As Welded >490 N/MM2 stress relieved 15 Hrs at 5800 c >420 N/MM2 |

As welded >600 N/mm2 stress relieved 15 Hrs at 5800 c >550 N/MM2 |

As welded >23 % stress relieved 15 Hrs at 5800 c >20 % |

As welded 180 J at +200 c 80 J at -500 c stress relieved 15 Hrs at 5800 c 200 J at +200 c 80 J at -500 c |

|

ZULFI E 9018-GAWS/ASME SFA-5.5: E 9018-G DIN 8529: E SY50 76 Mn1NiMo BH5 EN 499: E 50 6 1Ni MoB H5 |

Carbon: 0.07 Silicon: 0.35 Manganese: 1.10 Nickel: 1.20 Molybdenum: 0.50 |

As welded >520 N/mm2 stress relieved 15 Hrs at 5800 c >520 N/MM2 |

As welded >710 N/mm2 stress relieved 15 Hrs at 5800 c >680 N/MM2 |

As welded >23 % stress relieved 15 Hrs at 5800 c >20 % |

As welded 150 J at +200 c 60 J at -500 c stress relieved 15 Hrs at 5800 c 150 J at +200 c 50 J at -500 c

|

|

ZULFI E 9018-B3

AWS/ASME SFA-5.5: E 9018-B3 DIN 8575: E CrMo 2 B 26 EN 1599: E CrMo 1 B 32 H10

|

Carbon: 0.06 Silicon: 0.50 Manganese: 0.80 Chromium: 2.50 Molybdenum: 1.00 |

Temp at 7000 c Air Cool >440 N/MM2 Norm+Tem 15 Hrs at 9200 c >350 N/MM2 |

Temp at 7000 c Air Cool >580 N/MM2 Norm+Tem 15 Hrs at 9200 c >550 N/MM2 |

Temp at 7000 c Air Cool >23 %Norm+Tem 15 Hrs at 9200 c >24 |

Temp at 7000 c Air Cool 100J at +200 c Norm+Tem 15 Hrs at 9200 c 150 J at +200 c |

|

ZULFI E 9018-D1

AWS/ASME SFA-5.5: E 9018-D1 |

Carbon: 0.06 Silicon: 0.35 Manganese: 1.50 Molybdenum:0.35 |

>580 N/MM2 |

610 – 690 N/mm2 |

> 24 % |

180 J at +200 c 50J at -200 c

|

|

ZULFI E 10018-G

AWS/ASME SFA-5.5: E 10018-G DIN 8529: E Y 69 75Mn2NiCrMoBH5

|

Carbon: 0.06 Silicon: 0.50 Manganese: 1.50 Nickel: 2.10 Chromium: 0.40 Molybdenum: 0.40 |

>700 N/MM2 |

780 – 940 N/mm2 |

>17 % |

120 J at +200 c 55J at -200 c

|

|

ZULFI E 11018-GAWS/ASME SFA-5.5: E 11018-G DIN 8529: E Y 69 75Mn2NiCrMoBH5 |

Carbon: 0.06 Silicon: 0.50 Manganese: 1.80 Nickel: 2.20 Chromium: 0.40 Molybdenum: 0.40 |

>700 N/MM2 |

800 – 960 N/mm2 |

>17 % |

120 J at +200 c 60J at -600 c

|

|

ZULFI E 308L-16AWS/ASME SFA-5.4:E 308L-16 DIN 8556: E 19 9 LR23 |

Carbon: 0.03 Silicon: 0.40 Manganese: 1.00 Chromium: 19.0 Nickel: 10.0 |

>400 N/MM2 |

550 –620 N/mm2 |

> 35 % |

75 J at +200 c

|

|

ZULFI E 316L-16AWS/ASME SFA-5.4:E 316L-16 DIN 8556: E 19 12 3 LR23 |

Carbon: 0.03 Silicon: 0.80 Manganese: 0.80 Chromium: 18.5 Nickel: 12.0 Molybdenum: 2.70 |

>420 N/MM2 |

520 – 580 N/mm2 |

> 35 % |

65 J at +200 c

|

|

ZULFI E 309L-16AWS/ASME SFA-5.4: E 309L-16 DIN 8556: E 23 12 LR 23

|

Carbon: 0.03 Silicon: 0.80 Manganese: 0.70 Chromium: 24.0 Nickel: 13.0 |

>400 N/MM2 |

520 – 580 N/mm2 |

> 30 % |

60 J at +200 c

|

|

ZULFI E 347-16AWS/ASME SFA-5.4: E 347-16 DIN 8556: E 19 9 Nb R 23 |

Carbon: 0.025 Silicon: 0.90 Manganese: 0.80 Chromium: 19.0 Nickel: 10.0 Niobium: 0.40 |

>420 N/MM2 |

540 – 620 N/mm2 |

> 33 % |

60 J at +200 c

|

|

ZULFI E 310-16AWS/ASME SFA-5.4: E 310-16 DIN 8556: E 25 20 R 23 EN 1600: E 25 20 R 23 |

Carbon: 0.10 Silicon: 0.50 Manganese: 4.50 Chromium: 25.0 Nickel: 20.0 |

>400 N/MM2 |

550 –620 N/mm2 |

> 35 % |

100 J at +200 c

|

|

ZULFI E 308L-15AWS/ASME SFA-5.4:E 308L-15 DIN 8556: E 19 9 LB 20 |

Carbon: 0.03 Silicon: 0.40 Manganese: 1.00 Chromium: 19.0 Nickel: 10.0 |

>400 N/MM2 |

550 –620 N/mm2 |

> 38 % |

75 J at +200 c

|

|

ZULFI E 316L-15AWS/ASME SFA-5.4:E 316L-15 DIN 8556: E 19 12 3 LB 20

|

Carbon: 0.03 Silicon: 0.40 Manganese: 1.00 Chromium: 18.5 Nickel: 11.5 Molybdenum: 2.70 |

>420 N/MM2 |

520 – 600 N/mm2 |

> 35 % |

75 J at +200 c

|

|

ZULFI E 309L-15AWS/ASME SFA-5.4: E 309L-15 DIN 8556: E 23 12 LB 20

|

Carbon: 0.03 Silicon: 0.40 Manganese: 0.70 Chromium: 24.0 Nickel: 13.0 |

>400 N/MM2 |

520 – 600 N/mm2 |

> 35 % |

80 J at +200 c

|

|

ZULFI E 347-15AWS/ASME SFA-5.4: E 347-15 DIN 8556: E 19 9 Nb B 20 EN 1600: E 19 9 Nb B 42 |

Carbon: 0.025 Silicon: 0.40 Manganese: 1.00 Chromium: 19.0 Nickel: 10.0 Niobium: 0.40 |

>420 N/MM2 |

540 – 620 N/mm2 |

> 33 % |

70 J at +200 c

|

|

ZULFI E 310-15AWS/ASME SFA-5.4: E 310-15 DIN 8556: E 25 20 B 20 EN 1600: E 25 20 B 42 |

Carbon: 0.10 Silicon: 0.50 Manganese: 4.50 Chromium: 25.0 Nickel: 20.0 |

>400 N/MM2 |

550 –620 N/mm2 |

> 35 % |

100 J at +200 c

|

|

ZULFI E Ni CiAWS/ASME SFA-5.15 E Ni CI DIN 8573: E Ni BG-22

|

Carbon: 0.50 Iron: 2.00 Nickel: Balance |

>200 N/MM2

|

380 – 420 N/mm2 |

> 5 % |

Hardness HB 140

|

|

|

ZULFI E Ni Fe AWS/ASME SFA-5.15: E NiFe-CI DIN 8573: E NiFe-1 BG-22

|

Carbon: 0.50 Iron: Balance Nickel: 55.0 |

>300 N/MM2 |

420 – 460 N/mm2 |

>10 % |

Hardness HB 170

|

|

|

ZULFI E Ni Cu AWS/ASME SFA-5.15: E NiCu-B DIN 8573: E NiCu BG-22

|

Carbon: 0.50 Iron: 4.00 Nickel: Balance Copper: 30.0 |

>200 N/MM2 |

380 – 420 N/mm2 |

>1 5 % |

Hardness HB 150

|

|

|

ZULFI 500

|

Carbon: 1.30 Chromium: 20.0 Manganese: 1.40 |

53 – 58 HRC

|

|

|||

|

ZULFI 600

|

Carbon: 2.00 Chromium: 10.0 Manganese: 1.60 |

58 – 63 HRC

|

|

|||

|

ZULFI 600B |

Carbon: 0.50 Silicon: 0.40 Manganese: 0.30 Chromium: 7.00 Molybdenum: 0.50 Vanadium: 0.50 |

58 – 63 HRC

|

|

|||

ZULFI AL 99,5AWS/ASME SFA-5.3: E 1100 DIN 1732: EL-Al 99,5

|

Aluminium: 99.5 Min Others: 0.5 Max |

>30 N/MM2 |

80 N/mm2 |

>30 % |

|

|

ZULFI AL 5 Si

AWS/ASME SFA-5.3: E 4043 DIN 1732: EL-AlSi 5

|

Aluminium: Base Silicon: 5.00 Iron: 0.30 |

>90 N/MM2 |

160 N/mm2 |

>15 % |

|

|

ZULFI AL 12 Si

DIN 1732: EL-AlSi 12

|

Aluminium: Base Silicon: 12.0 Iron: 0.40 |

>80 N/MM2 |

180 N/mm2 |

> 5 % |

|

|